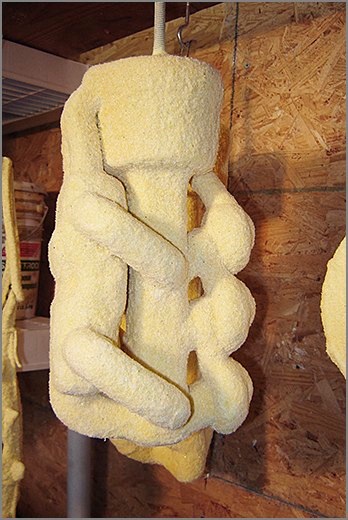

3. Investing or Building Up a Shell

A slurry of binder is applied to the wax followed by fine sand. The mixture is allowed to harden into a silica crust. This is repeated for several days until a thick (0.5”) shell forms around the wax.

This material possesses the requisite properties for bronze casting. It can:

- hold fine detail

-

-withstand the heat of molten bronze and

-

-be removed when the bronze has hardened